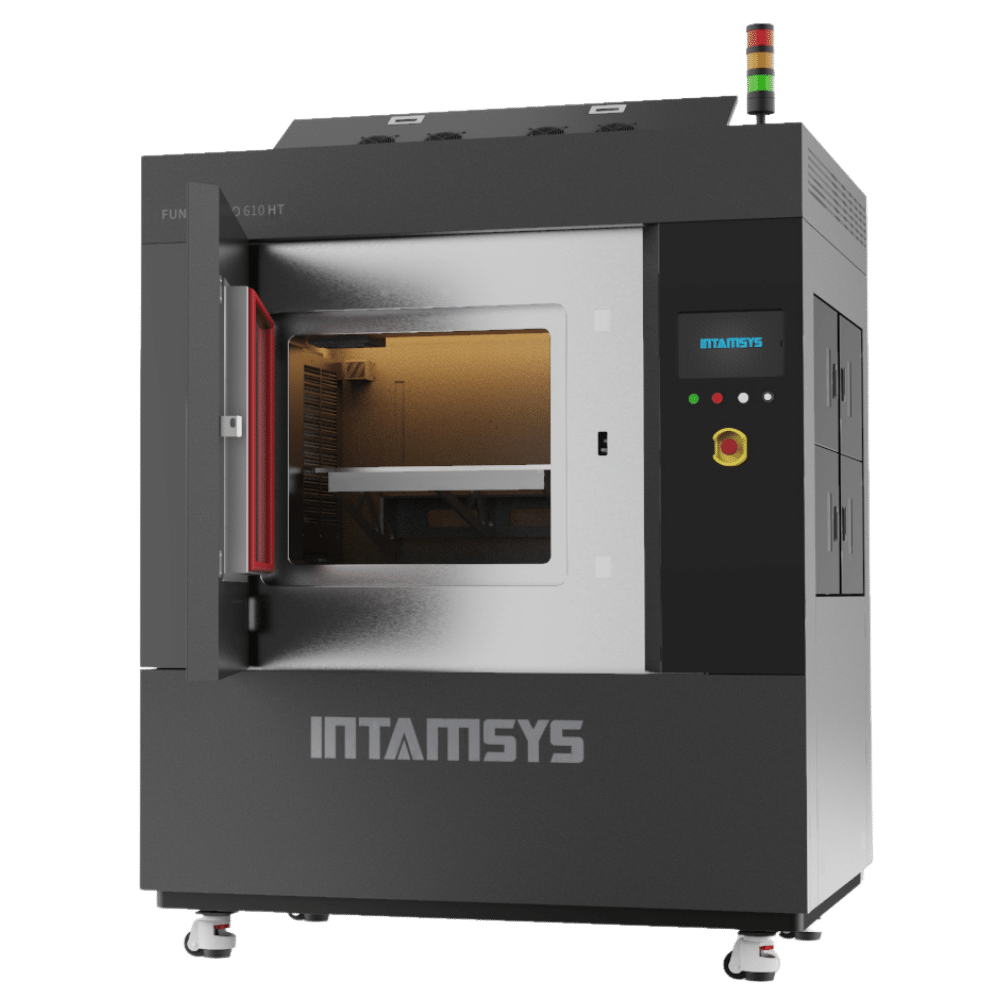

Funmat Pro 610HT

3D Print with Functional Materials at a Fraction of the Cost

Open Platform Allows for 3rd Party Materials when Necessary

Special Pricing for Research & Education

You might be interested to know:

- Where is my nearest INTAMSYS reseller?

- Can INTAMSYS printers run a certain material?

- Other questions for our 3D printing experts?

1 YEAR

WARRANTY

High-temp build chamber allows for accurate parts every time

Stong materials that can replace metal in many applications like ULTEM or Composites

Advanced Features for Industrial Applications

Liquid-cooled Dual Extruders with idle tip retraction; vacuum build platform; heated and dried filament bay; Automatic Leveling, and INTAMTouch User Interface makes the Funmat 610 Pro HT the engineer's choice for functional testing and end use parts on demand.

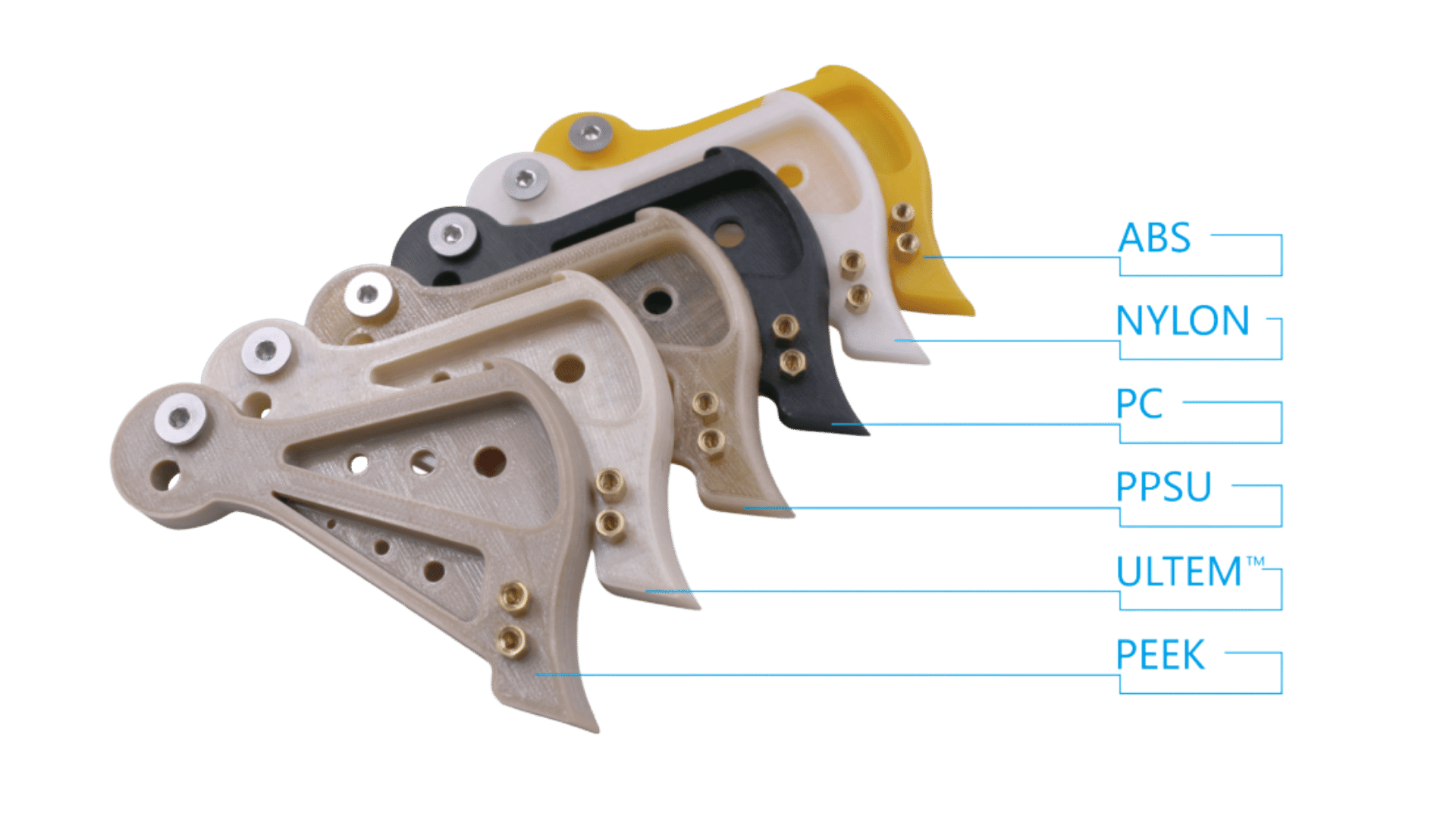

Additive Materials That Make A Difference

Strict Requirements Call For High Performance

INTAMSYS has partnered with the industries top material developers to deliver the best in performance and quality. Composite materials like carbon-filled nylon, or flame retardant material like ULTEM are very popular materials we offer. PEEK and many other

Sample Parts Printed From Popular INTAMSYS Materials

How Our Customers Are Using INTAMSYS Additive Technology

Every day our customers come to us with new application questions, and the answers usually end up "YES, INTAMSYS can do that too!"

Why INTAMSYS Funmat Pro 610HT?

Ready to Speak with an Expert

How can I see the INTAMSYS 3D Printers in action?

Do you have a material that can withstand 300F?

What are the site requirements for INTAMSYS 3D printers

Funmat Pro 610HT Tech Specs

| Positional Accuracy | XY: 12 μm / XY: 1.25 μm |

| Layer Resolution | 0.05-0.5 mm |

| Build Volume | 610 X 508 X 508 mm (24 x 20 X 20 in) |

| Max Extruder Temp | 500°C |

| Max Chamber Temp | 300°C |

| Connectivity | WiFi / USB |

| Filament Diameter | 1.75 mm |

| Supported Materials | PEEK/PEEK-CF/PEEK-GF/PEKK/ULTEMTM (PEI)*/PPSU*/PC-HT/PC/PC Alloys/PA-HT/PA/PA-CF/ ASA/ABS/HIPS/Carbon Fiber-Filled/GlassFiber-Filled/ESD-Safe, etc. |